The EM facility has a range of sample preparation facilities available.

Plasma cleaning

Plasma cleaning uses an Argon/Oxygen plasma to remove hydrocarbon contamination from samples, the facility has several plasma cleaners that can be used for cleaning both SEM and TEM samples. Plasma cleaning is suitable for metal/ceramic samples but may damage some materials e.g. polymers.

Systems available:

Henniker Plasma HPT-100 (G.303, PSI)

Henniker Plasma HPT-100 (BA.236, Eng A South Basement)

Fischione model 1070 NanoClean (BA.236, Eng A South Basement)

Sample coating

Sample coating may be performed for several reasons, but the most common is that a non-conductive sample needs to be imaged or analysed in an SEM.

Thin coatings of metal (3-10 nm) or carbon (10-20nm) are applied to a sample using a sputter or evaporative coating machine.

Without a conductive coating of metal or carbon, SEM analysis can be difficult due to the build up of charge on the sample (charging).

Different sputtering targets can used if sputter coating with a different metal is required.

Systems available:

Quorum Q150TES (BA.207, Eng A South Basement) – Metal sputter coater

Quorum Q150TES (BA.207, Eng A South Basement) – Carbon evaporation coater

Cressington 108 (BA.207, Eng A South Basement) – Pt sputter coater

Cressington 208 ( B13, Williamson Building) – Carbon evaporation coater

Quorum SC7640 (B13, Williamson Building) – Au coater

Precision cutting

Precision cut-off machines may be involved in both SEM and TEM sample preparation.

Delicate, heat-sensitive samples can benefit from being sectioned with a low-speed precision cut-off machine for SEM.

Methods for preparing cross-section TEM samples may also require use of such a machine to prepare thin slices of material ready for further thinning steps e.g. dimple grinding.

Systems available:

Minitom (BA.206, Eng A South Basement)

Ion beam milling (SEM)

Broad ion beam milling utilises Ar ions to sputter away the surface of samples.

Primarily used for removing layers of deformation (beilby layers) caused by mechanical prep to provide an excellent surface for EBSD/EPMA analysis.

May also be used for samples difficult to polish mechanically or to plasma etch grain boundaries.

Ion beam milling can heat samples by 50-60°C, so heat-sensitive samples may not be suitable for milling, unless a system with cooling is used.

Systems available:

Ilion II (BA.207, Eng A South Basement) – Planar and x-section samples, strict sample size limitations

Leica EM RES102 (BA.207, Eng A South Basement)

Ion beam milling (TEM)

Broad ion beam milling utilises Ar ions to sputter away sample material, for TEM samples material is sputtered away to thin the sample. Other gases may be used e.g. Xe but Ar is most common.

Primarily used for final thinning to electron transparency of TEM samples following other methods e.g. dimple grinding, electropolishing.

May also be used to remove amorphous Ga damage in samples prepared using a Ga FIB.

Systems available:

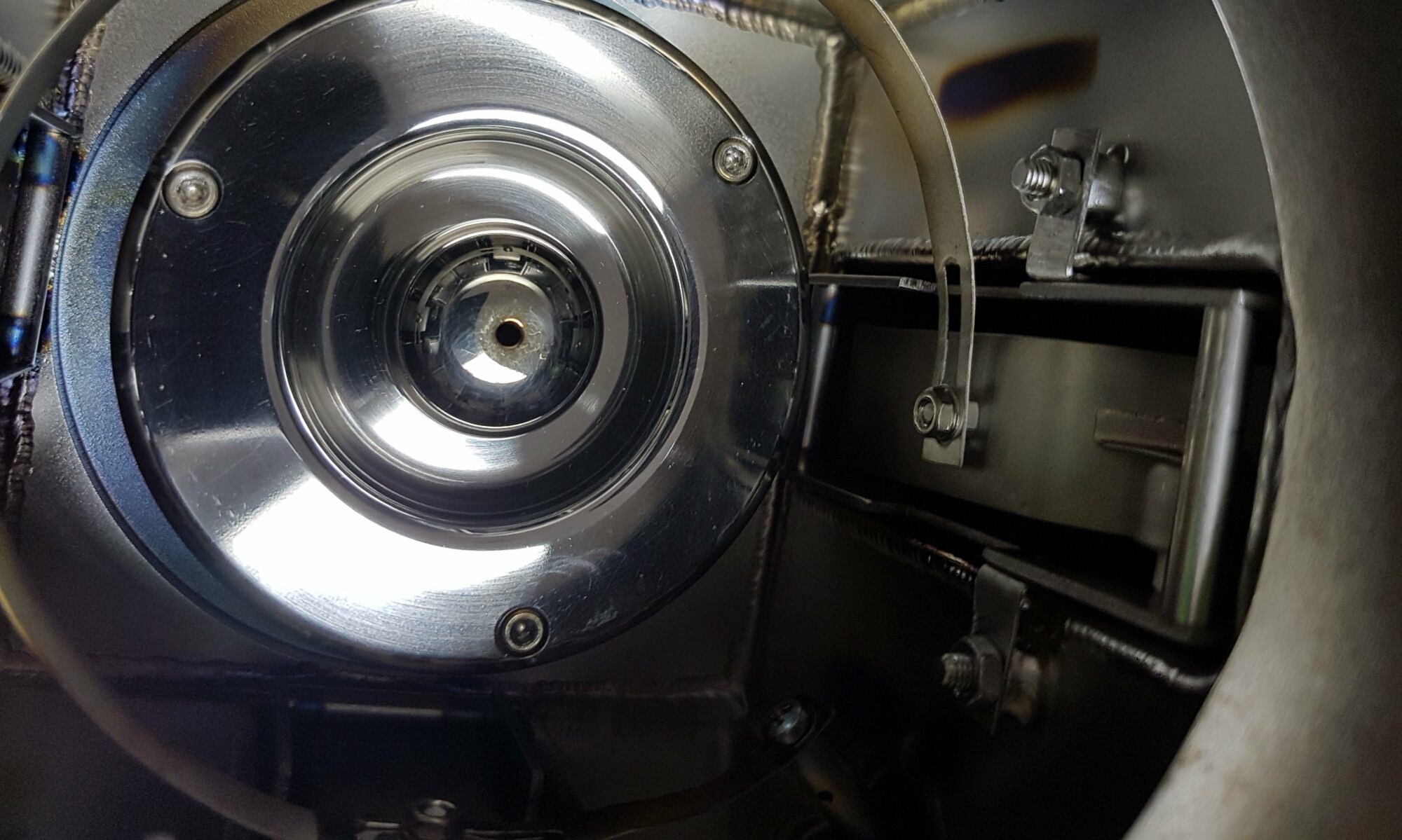

Gatan PIPS

Gatan PIPS II

Ultramicrotomy

Ultramicrotomy is a versatile preparation method for soft materials and can be used for both SEM cross-section sample preparation and for preparing ultra-thin (60-70nm) sections for TEM.

Some sample types may require embedding in resin prior to ultramicrotomy.

Equipment available:

Ultracut UCT ultramicrotome

EM UC6 ultramicrotome

TEM cross-section preparation

Ultramicrotomy is ideal for cross-section preparation of soft materials, unfortunately it cannot be used for everything. Other TEM cross-section prep methods can be time-consuming with multiple steps using different pieces of equipment.

FIB is often used if a site specific cross-section is required.

Equipment available:

Gatan x-section kit (BA.206, Eng A South Basement)

Gatan disc grinder (BA.206, Eng A South Basement)

Ultrasonic disc cutter (BA.206, Eng A South Basement)

Minitom (BA.206, Eng A South Basement)

Dimple grinder (BA.206, Eng A South Basement)

PIPS/PIPS II (BA.207, Eng A South Basement)

Allied MULTIPREP™ SYSTEM – 8″ (BA.206, Eng A South Basement)